by Kat Coogan, Business Development Manager

Business Development Manager Kat Coogan is responsible for delivering the business case strategy associated with each of the Futureworx start-up ventures, identifying route to market opportunities, opening doors to new customers and building strategic partnerships.

Kat has been working within sales, new business and bid management functions for over eight years with considerable experience in bid writing and management, solution and strategy planning, customer relationship management and account coordination. She has helped secure multi-million pound bids and campaigns across the Facilities Management and Aerospace sectors working with a mix of private companies and Government bodies.

A successful product is one that marries a brilliant idea with the right application. The latter part of this equation is as important as the former, and should have an equal role in driving decision-making.

In the case of Lilypad, we landed (literally) on offshore wind farm inspections as an ideal first application. In this article, I’ll explain why.

Supporting the profitable ramp-up of offshore wind

As we accelerate the net-zero transition, the coming decades will see unprecedented growth in the installed capacity of offshore wind farms worldwide.

In the UK alone, capacity is set to grow roughly fourfold from the current level of 12 GW to about 50 GW by 2030 under the British Energy Security Strategy, before potentially doubling again to 100 GW by 2050.

Likewise, global installed offshore capacity is forecast to grow rapidly from 55 GW in 2022 to roughly 370 GW by 2031—a sevenfold increase over the course of a mere decade.

For wind farm owners and operators, this growth obviously represents a transformative opportunity, but it also magnifies the importance of operational efficiency. Factors that currently weigh on profitability could easily become existential risks as wind farms increase in number, size, and distance offshore.

As the industry strives to meet the incredible level of demand for new capacity, and as efficiencies that currently seem optional become mandatory, Lilypad is perfectly positioned to support the profitable transformation of offshore wind.

Keeping the turbines spinning for longer

At present, the prevalent approaches to offshore wind farm inspections are rope access by human technicians, uncrewed aerial vehicles (UAVs) operating in visual line of sight (VLoS), and ground-based cameras.

These methods all involve the use of crew transfer vessels (CTVs) in order to transport technicians and equipment to turbines around a wind farm. Inspections carried out in this manner will need to be planned well in advance, with wind turbines being switched off for up to a day whilst the visual examination takes place, and with little flexibility allowed for inspection needs that may arise suddenly. Similarly, weather conditions are hard to take into account: operators may need to shut down turbines on high wind days, or postpone inspections (while still incurring costs) due to adverse weather.

Wind farm operators currently stick to planned maintenance inspections only, waiting until regulated intervals to complete potentially large scale checks and repairs. This decision comes at a cost: infrequent inspections are less likely to catch issues early on, when they could be addressed most effectively.

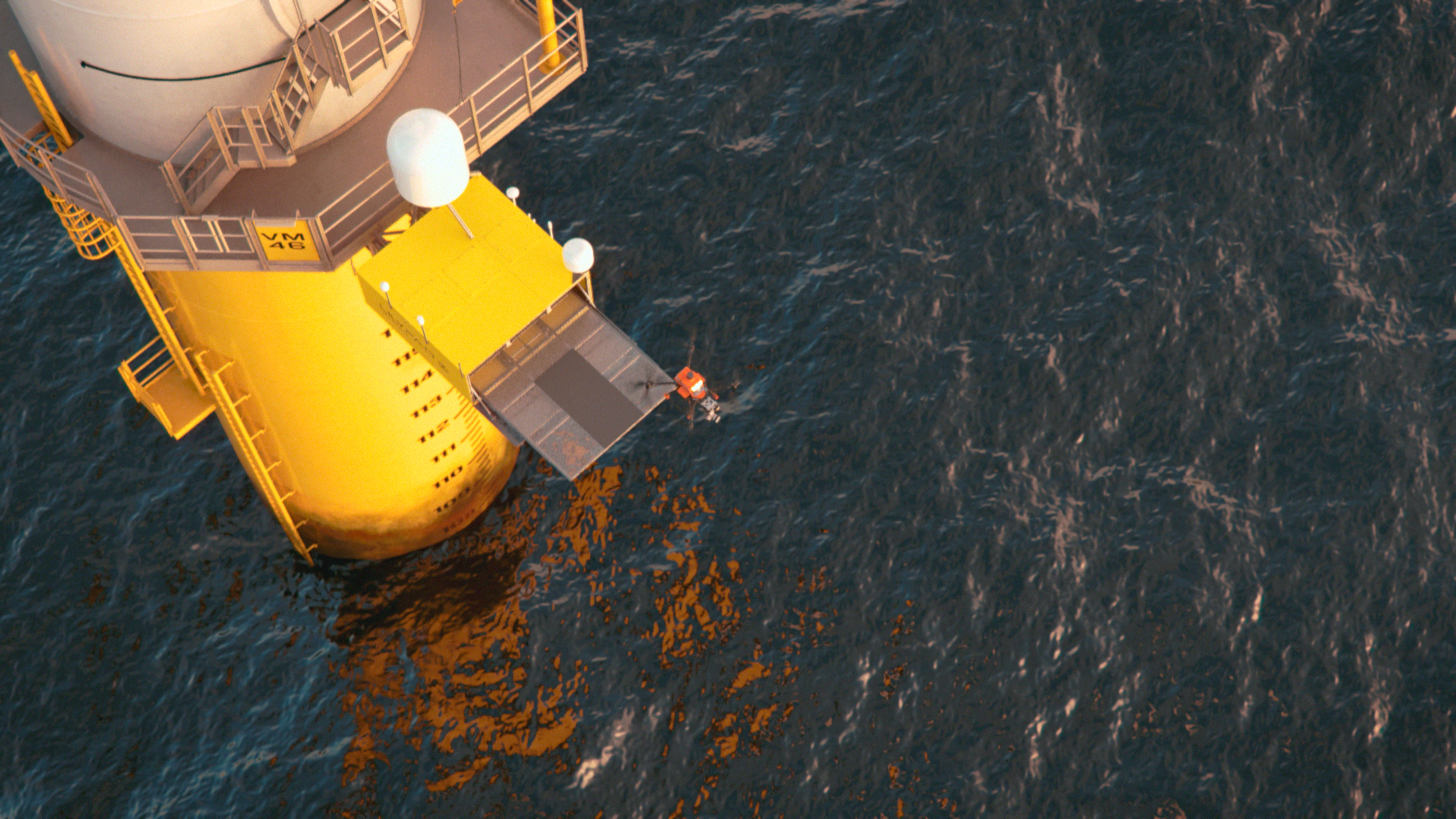

By contrast, Lilypad offers an ecosystem of multiple resident autonomous UAVs operating beyond visual line of sight (BVLoS). The UAVs “live” on site in turbine-mounted enclosures, and are monitored and operated by a single remote pilot stationed in an onshore command and control centre. Additionally, the UAV batteries can be rapidly swapped out, meaning a Lilypad can land and take off on a full charge within minutes. The upshot is that Lilypad’s UAVs are constantly within striking distance of where they will be needed, so inspections can be conducted dynamically and on demand.

Additionally, inspections conducted by a Lilypad UAV can be completed extremely quickly—specifically, all three blades will take just 15 minutes. From an operator’s perspective, this is an obvious economic benefit and maximises turbine uptime while also further enhancing flexibility around inspection timing.

This degree of flexibility will let operators conduct more frequent inspections without incurring the punitive level of logistical difficulty and financial burden outlined above.

In turn, increasing the frequency of inspections will allow for earlier identification of potential issues with turbine blades—and the earlier an issue is detected, the more effectively it can be dealt with. Even “minor” aesthetic issues such as chips, cracks or indentations can act as weak points if left unchecked, eventually leading to the development of major faults.

Wind turbine inspections are crucial to the longevity of the wind turbine, and a system like Lilypad can maximise turbine uptime (and therefore revenue) for offshore wind farm operators by enabling faster and more flexible inspections.

Reducing operational burden

As offshore wind becomes an increasingly prominent force in renewable energy generation, wind farms are becoming logistically harder to maintain. With complex operation and maintenance (O&M) schedules to plan, maintain and execute, wind farm operators are facing increased downtime and conflicting priorities arising from CTV usage and related resources.

This is exactly the kind of near-future problem Lilypad addresses perfectly. Lilypad’s infrastructure is agnostic of distance from shore and does not scale linearly with the number of turbines, since a single remote pilot can task and monitor multiple inspection UAVs.

Additionally, Lilypad is sold as a complete service offering and only relies on the customer during the operational setup to ensure we have adequate infrastructure and UAVs to meet their inspection demand and a complete maintenance schedule. The customer is then released of the burden of planning and completing inspections, allowing them to focus on other priorities within the wind farm.

Powered by 100% renewable energy

As we continue on the path to net zero, the infrastructure supporting renewable energy generation should itself be as sustainable as possible. In this regard, current inspection methods fall short of the mark, incurring their own carbon footprint and being heavily reliant on CTV trips and extensive marine logistics.

With their resident nature, Lilypad is set to support the decarbonisation of O&M activities in the wind farm and clean maritime operations by reducing the frequency of CTV trips. Additionally, the UAVs and enclosures draw their power from the very turbines whose lifespans they are prolonging.

In summary…

In this article, I have outlined why we at Futureworx believe offshore wind farm inspection is the ideal first application for Lilypad. In short, Lilypad can realise economic, sustainable and operational benefits through more frequent and faster inspections.

I have mainly focused on a few of Lilypad’s key operational and economic advantages over established inspection methods, and there are some areas I haven’t even touched on—such as the safety benefits of avoiding incidents and accidents associated with rope access by technicians.

I have also not discussed the significant potential to employ valuable new insights gained from Lilypad’s data gathering and analysis capabilities, as this will be the focus of a future article.

I should also mention that turbine blade inspection is not the only potential offshore wind application for Lilypad: we also see opportunities to adapt the system to include inspection of other parts of wind farm infrastructure, such as turbine jackets and platforms, or offshore power substations.

Additionally, while offshore wind is our focus as the initial application for Lilypad, there are plenty of other exciting potential applications of Lilypad that we look forward to unveiling in the near future.

More information on Lilypad will be available when the product is first publicly showcased during the Global Offshore Wind Exhibition in London on June 14th, 2023. If you’re visiting the show, please stop by and visit the Futureworx team on stand A66.

You can also learn more from the dedicated Lilypad webpage on our Futureworx website: https://marshallfutureworx.com/lilypad.